Function of dental suction Units

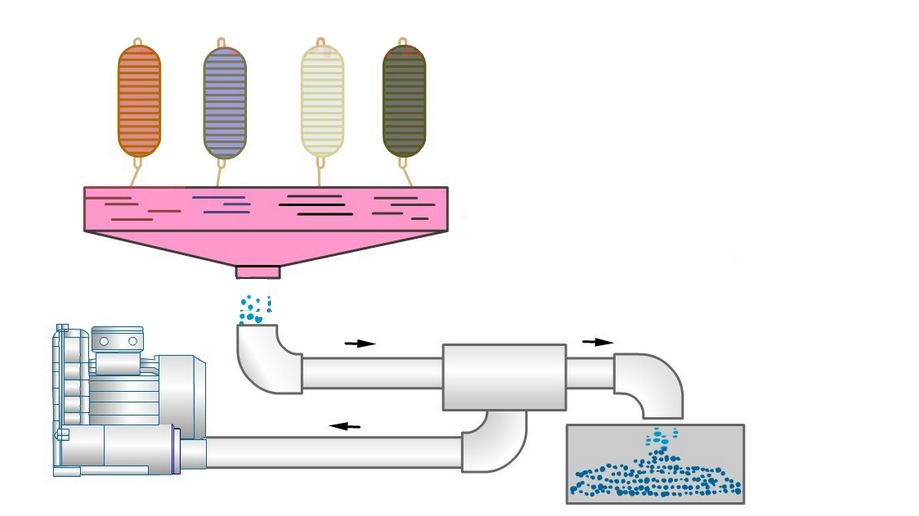

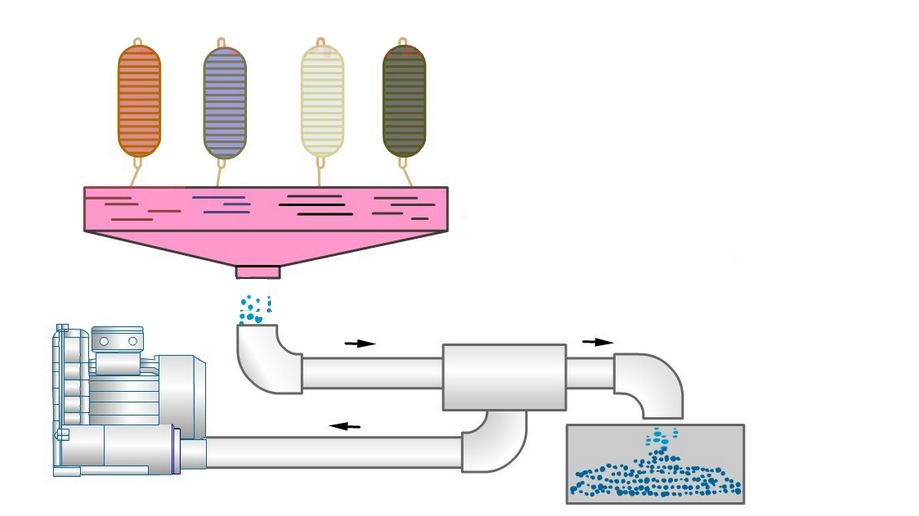

1. Suction and discharge can be carried out at the same time without suction blind spots

2. The suction force is stable and the suction amount is large

3. Centralized collection and separation to avoid secondary pollution

4. Delay function of suction, so that there is no back flow in the pipeline to avoid peculiar smell in the clinic

5. Save space, save energy and water, and improve economic benefits

6. simple maintenance, durable, safe use, users can rest assured

7. Protect doctors' health and prevent cross infection

8. Care for patients, no swallowing reaction, improve work efficiency and increase patient turnover rate

Characteristics of dental suction Units

1. High pressure, large air volume, low noise and light weight.

2. The aluminum alloy material is adopted, which greatly reduces the weight and achieves the purpose of light weight.

3. The motor is IP55 design (above 1hp), fully closed external fan-shaped aluminum frame motor, and special axis design, which can be used for a long time.

4. Special blade design, high pressure, large air volume, low noise and long service life.

5. Special air volume damper has high air volume control stability and easy operation.

6. Complete styles, large inventory and quick delivery.

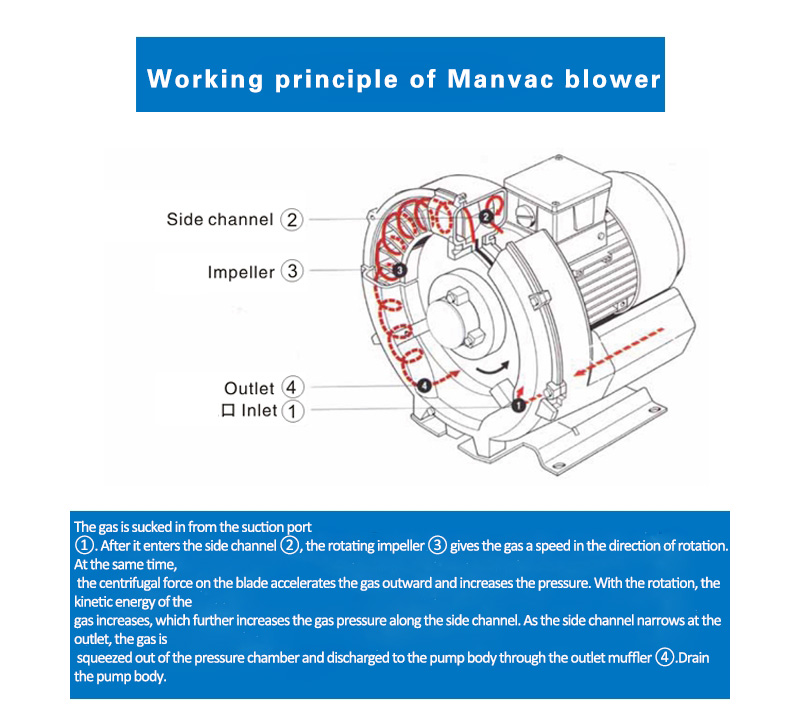

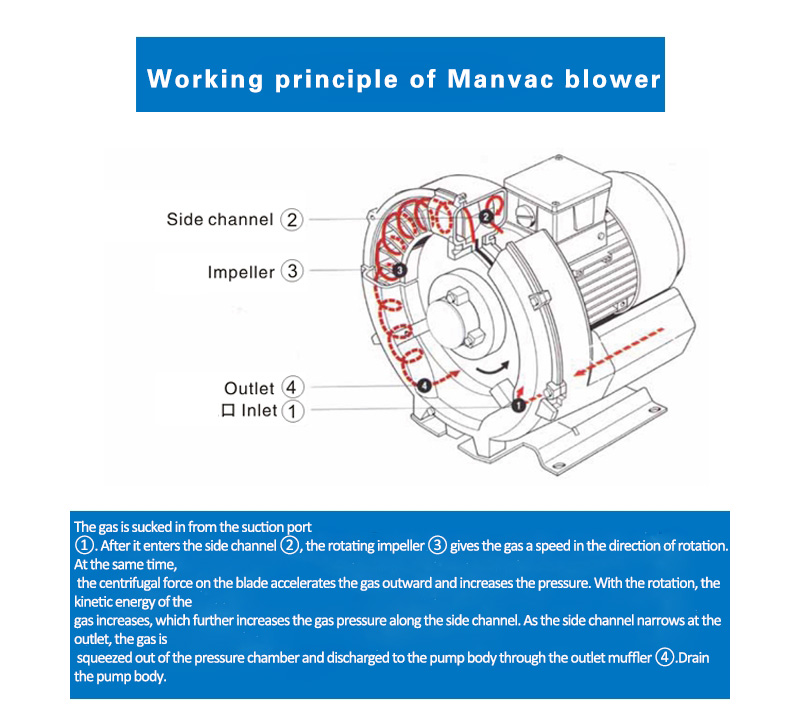

Working principle of side channel blower

Performance characteristics of side channel blower for dental equipment

1. Low energy consumption: all methods such as blowing, spraying and suction are effective for it, and there is a conservative design in the range of high pressure. When the use case is industrialized, the Manvac blower still runs safely.

2. Easy installation: it can be installed at any time in the use place for compressed air or vacuum pumping, and can be installed in the horizontal or vertical direction at will 3. High reliability: there are no other moving parts except the impeller, and the impeller is directly connected to the motor, which is not driven by gears or transmission belts, so the reliability is high, and it is easy to maintain.

3. Low vibration: the mechanical precision is high, and the other parts of the rotating part have undergone extremely precise balance design, testing and correction, and the vibration rate is very low.

4.High reliability: there are no other moving parts except the impeller, and the impeller is directly connected to the motor, which is not driven by gears or transmission belts, so the reliability is high, and it is easy to maintain.

5. Save space: design to reduce space waste.

Spanish

Spanish English

English manager@manvac.cn

manager@manvac.cn +86-15014788350

+86-15014788350 Spanish

Spanish English

English