Spanish

Spanish English

English sales@manvac.cn

sales@manvac.cn +86-15014788350

+86-15014788350

Spanish

Spanish English

English

Working Principle:

Super air knives are generally made of aluminum or stainless steel. After compressed air enters air

knives, the air volume is increased by 20 to 40 times by Cohen's effect principle and special structure

of the air knives to form a thin, high-strength and large-flow impact air curtain. The compressed air

intake volume is directly proportional to air output volume, the maximum wind speed can reach 80 m/s.

Product Advantages:

1. Low noise, in most cases only 69 decibels (pressure 5.5 bar, about 60 decibels), 11 times lower than that of conventional drill pipe air curtain.

2. compressed air is saved, and the air consumption is 63% less than that of conventional drill pipe air curtain.

3. The air flow of the super air knife is balanced, and the air amplification ratio can reach 40: 1.

4. Super air knife has no moving parts and is made of aluminum or stainless steel.

5. Small size, easy installation and maintenance-free.

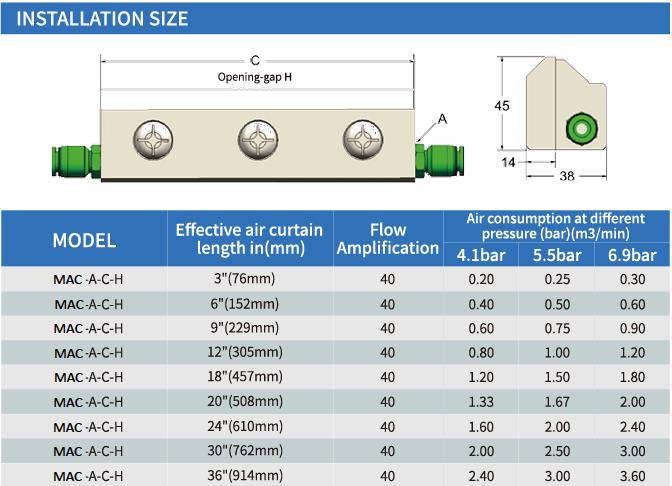

6. It can provide a variety of air curtain widths (100-1220mm) with adjustable airflow intensity.

7. Super air knife can replace traditional fan and air blowing pipe.

8. A dense, continuous and gapless air curtain can be formed to effectively block the invasion of harmful gases, thus playing the roles of isolation, shielding and strong purging.

Product Applications:

Applicable to auto industry, electronics industry, chemical industry, food and medicine industry, metal industry, beverage canning and bottle making industry, rubber plastic industry and printing industry.

1) cooling and drying parts after cleaning process

2) after the beverage filling process, the beverage is dried by high-pressure air and then labeled

3) plate cleaning with rigid rolling mill

4) Conveyor belt cleaning, smoke exhaust during engine test

5) Dehydration and Drying of Vegetables and Fruits Before Packaging

6) Cleaning the working environment on the production line and drying or cleaning the fabric

7) pretreatment before electroplating or painting

8) Coating Machines in Paper Making and Printing Industry, Opening of Packaging Bags when Packaging Machines Work

Instructions:

1. Air knives can be assembled into air knives with longer length at will, and any length can be customized according to customer's requirements (maximum length of a single air knife is 2000mm).

2. The conventional materials of super air knives are AL6061 and SUS304. Please explain if you have any other special requirements.

3. For orders beyond the above data range, please call our company at +86 15014788350 for consultation.

Notices:

1. Pay attention to avoid colliding with the knife edge. The compressed air used should avoid containing too coarse impurity particles to avoid blocking or damaging the knife edge.

2. The width of the tuyere has been calibrated according to the customized requirements when the product leaves the factory. If necessary,

please deliver it to the original merchant or professional for calibration to avoid weakening the product performance due to self-calibration.