Spanish

Spanish English

English manager@manvac.cn

manager@manvac.cn +86-15014788350

+86-15014788350

Spanish

Spanish English

English

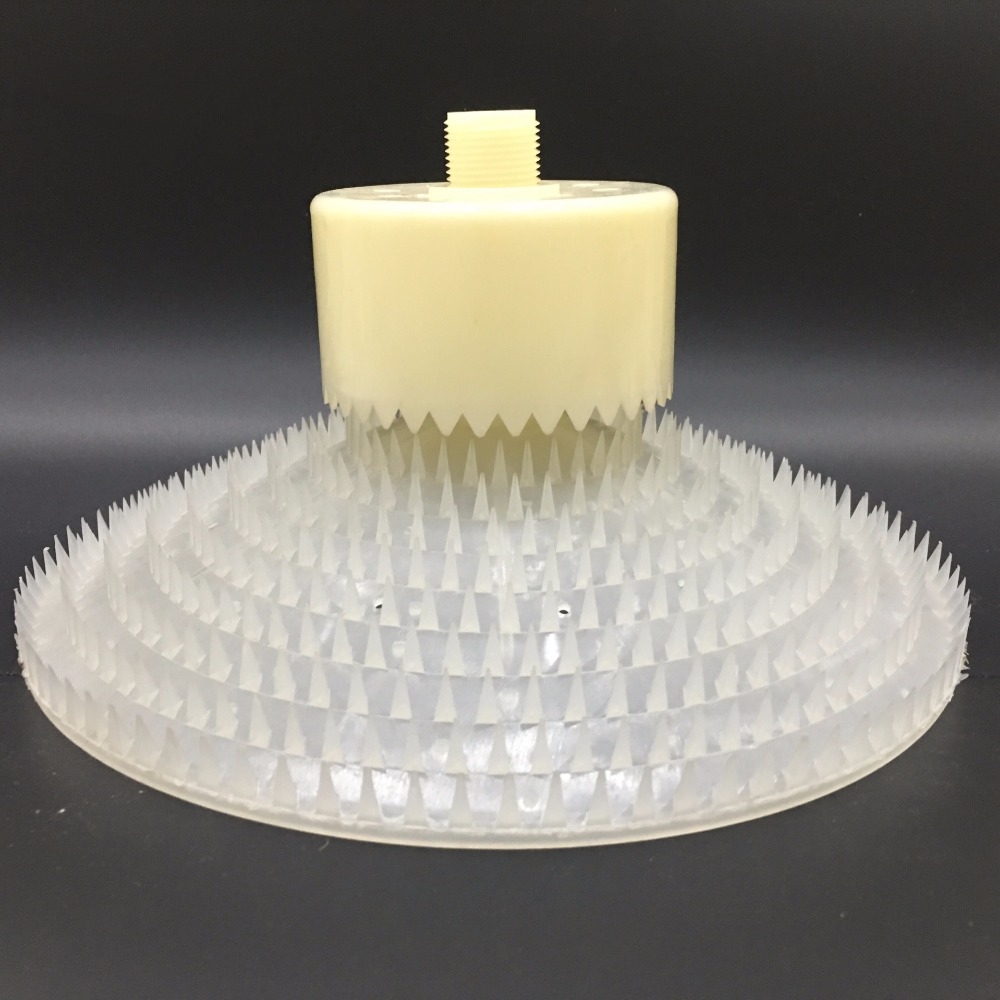

Rotary mixed aeration device for the use of multi-slice cutting patterns for aeration and oxygenation, when Francis entered the air-Aerator, the airflow through the first two spiral cutting system, cutting into the lower deck of the multi-storey saw tooth-cloth. The first, multi-cutting, so that cut bubble bubble, this has greatly enhanced the utilization of oxyge, a gas uniform cloth, and oxygenation efficient characteristics.

|

Product name |

Rotary mixed aeration device |

|

Model |

φ 260 |

|

Air exhaust flow |

100-30 L/min/set |

|

Water depth |

4-8 M |

|

Service area |

0.5-0.8 M2/set |

|

Oxygen utilization rate |

21.5 |

|

Oxygen transfer capacity |

0.165 Kg/h |

|

Resistance loss |

<30Pa |

Products Show

Application:

A. aeration tank in industrial and urban wastewater treatment plant, which uses blower as air source.

B. activated sludge method and contact oxidation method.

C. the technology renewal and reconstruction of existing old aerator.

Technology advantages:

1. adopt big holes to exhaust gas and lead flow, use several structures to cut and scatter airflow; its a modern and advanced aeration-diffusion method.

2. the equipment has characteristics of non-blocking and small air resistance, which can keeping producing air bubbles evenly and densely. Compared with micro-pore aerator, its efficiency wont deteriorate gradually.

3. the material adopted wont age easily, guarantee measures are complete, cleaning, replacing and repairing are not needed.

4. resitance loss is small, ≤30Pa.

5. aeration device often takes blower running at a low pressure to supply air, the smaller the resistance is, the higher the efficiency will be.