Home>How to Choose Air Knife Products

Products Categories

Contact Us

Tel: 15014788350

Fax: 0769-22800432

Mob: +86-15014788350

Email:

manager@manvac.cn

Add: Building C,Ming Zhi Shang Sha,Xi Ping,Nancheng,

Dongguan City, Guangdong Province,China 523000

How to Choose Air Knife Products

2022/10/31

MV-50

How to Choose Air Knife Products Air Knives, also called air knives, can be driven by vortex fans or high-pressure centrifugal fans (instead of compressed air with high energy consumption). It uses different fans to cooperate with air knives, which can blow dry dust and moisture on the surface of objects in time.  Application of Traditional Koenda Air Knife in Packaging Industry In the industrial field, there are many applications of wind blowing to remove water and dust, such as blowing off dust and moisture on steel plates, aluminum alloy profiles and other planes, blowing off moisture on the surface of bottles such as beverage bottles and packaging cans, blowing off impurity dust and residual liquid on the surface of products, and cleaning the conveyor belt. Under the condition of compressed air supply, air knives can perfectly meet these applications, among which Koenda effect air knives, spider hand (eagle beak) air knives and stainless steel air knives are very popular among users.

Application of Traditional Koenda Air Knife in Packaging Industry In the industrial field, there are many applications of wind blowing to remove water and dust, such as blowing off dust and moisture on steel plates, aluminum alloy profiles and other planes, blowing off moisture on the surface of bottles such as beverage bottles and packaging cans, blowing off impurity dust and residual liquid on the surface of products, and cleaning the conveyor belt. Under the condition of compressed air supply, air knives can perfectly meet these applications, among which Koenda effect air knives, spider hand (eagle beak) air knives and stainless steel air knives are very popular among users.

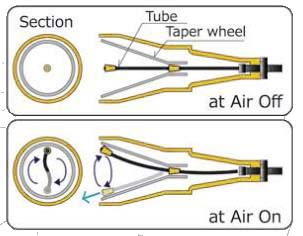

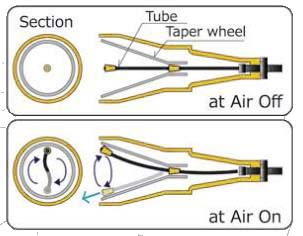

However, in some specific industry production lines (wine and beverage filling lines), the blowing forces of two air knives counteract each other, which will lead to a dry blind area. The air knives used for this purpose are large in size, and when installed, they are blocked by guardrails and cannot be close to the drying target, so it is necessary to equip a blower with higher power, which causes a certain length of waste in energy consumption. Now, the new rotary air knives introduced by Manvac Electromechanical Co., Ltd. have solved the appeal problem. New Ming Kai Rotary Nozzle (Air Knife) This is a new type of air knife, which can also be used as an air gun nozzle according to users' requirements. MV-50 rotary nozzle is very suitable for large-scale or wide-range water removal, and has been widely used in industries such as workpiece processing dust blowing, plastic parts dust removal, water removal, metal processing and oil removal.

When the MANVAC rotary nozzle is connected to the air source, the pipe starts to move under the pressure and rotates along the inner wall of the conical wheel in the nozzle movement range. When you touch the nozzle of Ming Kai rotary nozzle with your hand, you will feel the intermittent impact of air. This is the shock wave. The air impact force generated by the shock wave generated by the pipe rotation is the same as the speed of the pipe rotation. (MV series: more than 20 revolutions per second). The cone (white cover) is a component that rotates synchronously with the nozzle tube. Through this synchronous rotation, the friction resistance can be reduced and the dust can be kept away.

Spanish

Spanish English

English manager@manvac.cn

manager@manvac.cn +86-15014788350

+86-15014788350 Spanish

Spanish English

English Application of Traditional Koenda Air Knife in Packaging Industry In the industrial field, there are many applications of wind blowing to remove water and dust, such as blowing off dust and moisture on steel plates, aluminum alloy profiles and other planes, blowing off moisture on the surface of bottles such as beverage bottles and packaging cans, blowing off impurity dust and residual liquid on the surface of products, and cleaning the conveyor belt. Under the condition of compressed air supply, air knives can perfectly meet these applications, among which Koenda effect air knives, spider hand (eagle beak) air knives and stainless steel air knives are very popular among users.

Application of Traditional Koenda Air Knife in Packaging Industry In the industrial field, there are many applications of wind blowing to remove water and dust, such as blowing off dust and moisture on steel plates, aluminum alloy profiles and other planes, blowing off moisture on the surface of bottles such as beverage bottles and packaging cans, blowing off impurity dust and residual liquid on the surface of products, and cleaning the conveyor belt. Under the condition of compressed air supply, air knives can perfectly meet these applications, among which Koenda effect air knives, spider hand (eagle beak) air knives and stainless steel air knives are very popular among users.